Wertel Oberfell is a product design firm founded in Germany in 2007, with offices in Berlin and Munich, which has recently launched a truly unprecedented model of shoe. It is a classic shape of boot, with the difference that it is made from a 3D-printed material with a pattern, developed by the firm itself, which allows for the shoe to adapt to the ergonomics of the foot throughout the day.

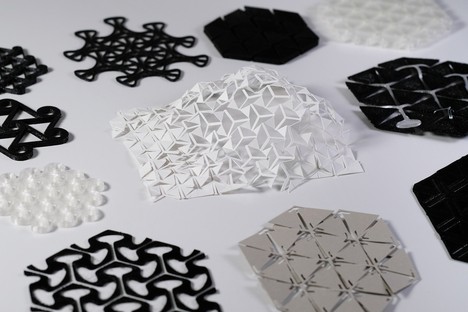

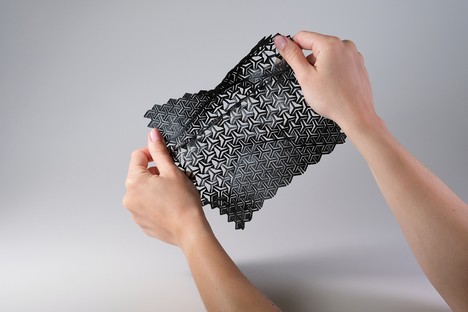

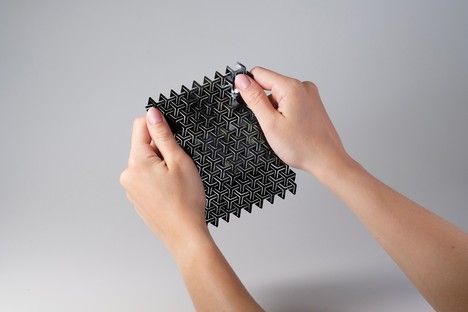

The adaptability of the Wertel Oberfell-designed shoe is an intrinsic consequence of the auxetic properties of the structures developed by the firm. Indeed, auxetic materials have a unique characteristic, namely that they have a negative Poisson’s ratio. In other words, these materials, if subjected to tensile stress, open up like an umbrella, expanding in a direction transverse to that of the force being applied. And vice versa: when subjected to compression, they ‘close up’, resulting in the material itself necking. The main uses of these structures thus far include body armour, packaging, impact protection, sponges and clothes, but the potential applications as yet unexplored are boundless.

Jan Wertel and Gernot Oberfell, founders of the firm, told us about how their research got underway in an interview: “We have been working with 3D printing for almost two decades now, in the beginning for model making, but in the mid 2000s we started using this new tool in a more experimental way, combining it with the new possibilities that parametric CAD modelling offered. Our first project with auxetic structures was a white cane for visually impaired people, Sense Five. Here, an auxetic pattern was used as a feedback element that warns the user of obstacles by changing its surface. Auxetic Wear started in the beginning of 2022, after diving deeper into the topic and looking for other uses of these incredible structures. We had a few ideas how to use it, ranging from furniture to medical products, but finally settled on utilising it for a shoe.”

Why did you decide to start with a shoe, of all things? “The shoe (or boot) was the best topic to show the aesthetic and functional side of auxetic structures. We have the need of comfort which works well with auxetics, because they can shift their shape on a very localised level and thus adapt to the individual foot. For us it also just looks very beautiful, especially in motion when it expands and contracts, so we wanted to bring that element to the forefront. In our research we found a lot of performance orientated sneakers, but not so much everyday foot wear. So it made more sense for us to design something that would appeal to a broader audience. For us it is sometimes more interesting to infiltrate the established with the new and unknown.”

What would you say about your project in terms of environmental sustainability?

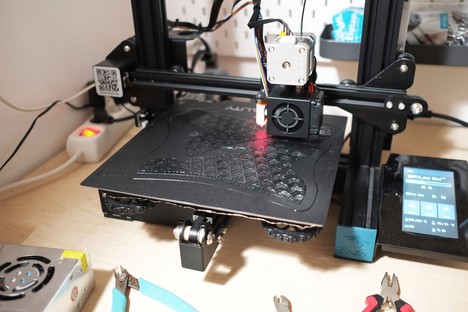

“For now the design is not necessarily ecologically sustainable, because the filament we used is not compostable, and since we glued the elements it is hard to repair the upper part. But, this is also just a prototype. In the beginning we were not fixated on 3D printing, and tried other methods and materials (like vegan leather cut with a cutting plotter), which could still be relevant on a later stage, but finally settled on the 3D printer with a flexible filament. We recycled used soles for the models, that could be another interesting idea, to reuse soles and adapt the upper part to them. On the plus side, we made the printing very efficient by printing it flat and forming it afterwards, it is a single material so you could easily recycle it, and in theory you could argue that the production method would allow a localised production, which may help with local crafts people and minimise transport (although you may still have to transport the material first).”

In order to create a working prototype of their auxetic shoe, the designers first had to learn the cobbler’s trade, allowing them to develop the paper patterns that lead from the 2D surface of the fabric to the 3D shape of the finished shoe. This transition from two to three dimensions - according to Oberfell and Wertel - was one of the most interesting parts of the entire research project, and one that will more than likely see further development.

The last question has to do with the product’s potential for commercial launch and future developments of the project. Gernot and Jan’s response is relaxed, inspired and down-to-earth: “Since this is what we call a “Lab” project, which means it is self initiated and non-profit, we will see when we go into the next steps. At the moment this is more like a statement to inspire people and to maybe start a conversation.”

Cib

Project: Auxetic Wear by WertelOberfell

Designers: Jan Wertel, Gernot Oberfell

Project assistant: Rebecca Meixner

All images courtesy of WertelOberfell

http://www.werteloberfell.com/